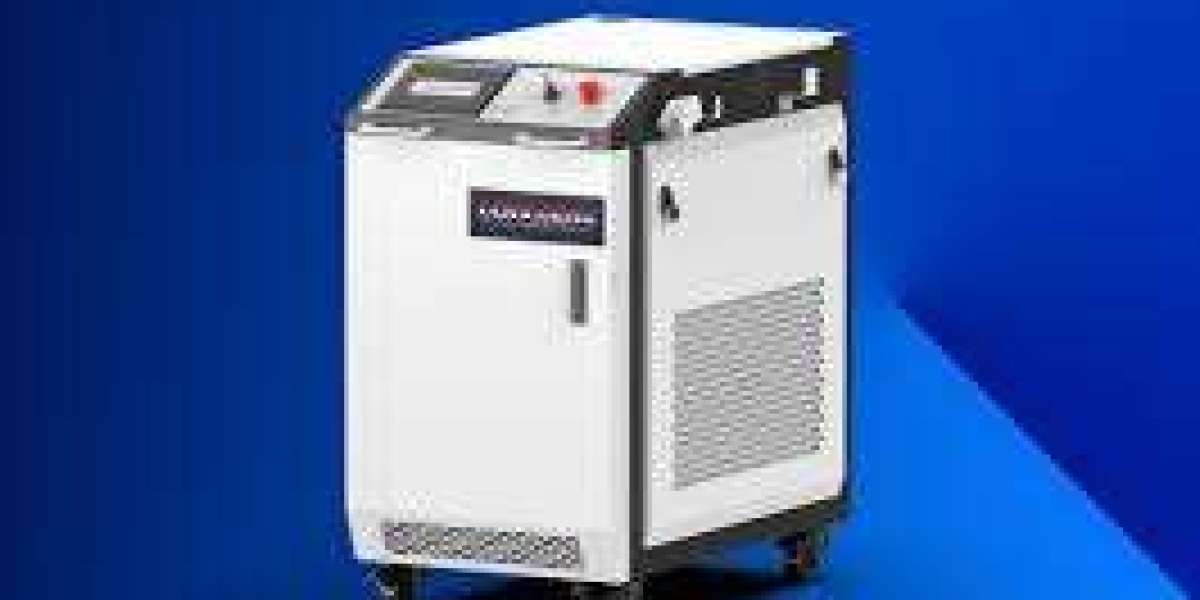

Rust and corrosion can be a nightmare for metal surfaces, but traditional cleaning methods often involve harsh chemicals, abrasive tools, or tedious manual labor. Enter the laser rust removal tool, a cutting-edge solution that delivers unmatched precision, efficiency, and eco-friendliness. Whether you're restoring vintage cars, maintaining industrial equipment, or working on delicate artifacts, laser cleaning is transforming the way we tackle rust.

How Does a Laser Rust Removal Tool Work?

A laser rust removal tool uses high-intensity laser beams to vaporize rust, paint, and other contaminants without damaging the underlying metal. The process is non-contact, meaning there’s no physical wear on the surface. The laser’s energy breaks down rust particles, which are then removed via an integrated extraction system, leaving behind a clean, smooth finish.

Key Benefits of Laser Cleaning

Precision & Control – Unlike sandblasting or grinding, lasers target only the rust, preserving the integrity of the base material.

Eco-Friendly – No toxic chemicals or abrasive media means safer workspaces and reduced environmental impact.

Cost-Effective – Lower long-term costs with minimal consumables and reduced labor time.

Versatile – Works on various metals, including steel, aluminum, and even delicate historical artifacts.

Safe & Efficient – Operators can work with minimal protective gear, and cleanup is hassle-free.

Who Can Benefit from a Laser Rust Removal Tool?

Automotive Restorers – Perfect for reviving classic cars without damaging original parts.

Industrial Maintenance Teams – Ideal for cleaning machinery, pipelines, and structural components.

Art Conservators – Safely restore sculptures, monuments, and historical metalworks.

Manufacturers – Improve surface prep before welding or coating applications.

Why Choose Laser Over Traditional Methods?

Traditional rust removal techniques often come with drawbacks:

Sandblasting creates dust and requires extensive cleanup.

Chemical Strippers pose health risks and environmental concerns.

Manual Grinding is time-consuming and can damage surfaces.

A laser rust removal tool eliminates these issues, offering a faster, cleaner, and more sustainable alternative.

Final Thoughts

As industries shift toward smarter, greener solutions, laser cleaning stands out as a game-changer. Whether you're a professional or a hobbyist, investing in a high-quality laser rust removal tool ensures superior results with minimal effort.